SSCH160-6000-10000 ชุดทดสอบไดนาโมมิเตอร์ปั๊มไฮดรอลิกอุตสาหกรรม 160kW

1. ภาพรวมระบบชุดทดสอบไดนาโมมิเตอร์ปั๊มไฮดรอลิกอุตสาหกรรม SSCH160-6000-10000 160kW

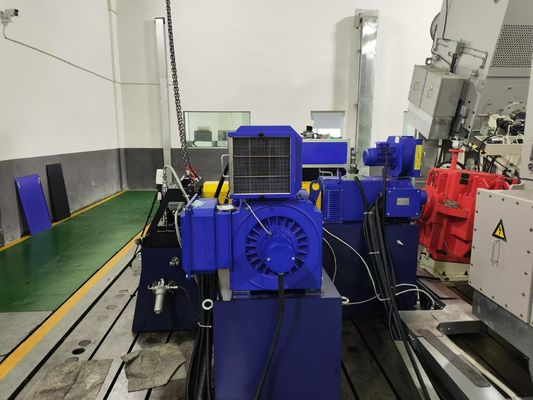

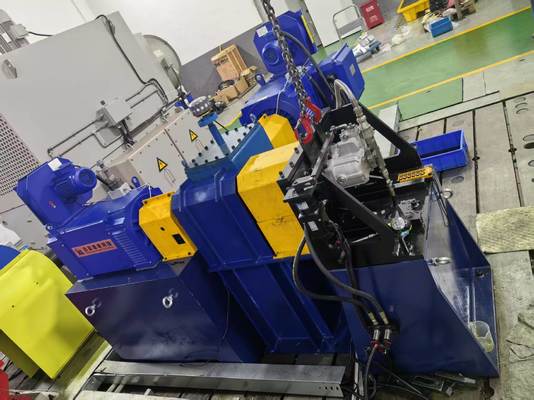

ชุดทดสอบไดนาโมมิเตอร์ปั๊มไฮดรอลิก SSCH160-6000-10000 ได้รับการออกแบบมาโดยเฉพาะสำหรับระบบไฮดรอลิกอุตสาหกรรมสำหรับงานหนัก โดยมีการรวมไดนาโมมิเตอร์ไฟฟ้ากำลังสูง 160kW, ปั๊มไฮดรอลิกแรงดันสูงเกรดอุตสาหกรรม, โมดูลโหลดหลายสภาวะ, และระบบวัดและควบคุมเกรดอุตสาหกรรม ทำให้สามารถทดสอบประสิทธิภาพของปั๊มไฮดรอลิกอุตสาหกรรมได้อย่างครอบคลุมภายใต้แรงดันสูง (50MPa), โหลดสูง (โหลดต่อเนื่อง 160kW) และสภาวะการทำงานคงที่ ระบบรองรับการหมุนเวียนพลังงานไฟฟ้ามากกว่า 85% และเหมาะสำหรับการสอบเทียบประสิทธิภาพ, การตรวจสอบความทนทาน 1000 ชั่วโมง, และการจำลองความผิดพลาดของปั๊มไฮดรอลิกแรงดันสูงที่ใช้ในเครื่องฉีดขึ้นรูป, เครื่องจักรโลหะวิทยา, และอุปกรณ์การขุด ซึ่งตรงตามข้อกำหนดการทดสอบความน่าเชื่อถือสูง, โหลดสูง, และวงจรยาวของอุตสาหกรรมไฮดรอลิก

2. ส่วนประกอบระบบชุดทดสอบไดนาโมมิเตอร์ปั๊มไฮดรอลิกอุตสาหกรรม SSCH160-6000-10000 160kW

1) ปั๊มไฮดรอลิกแรงดันสูงสำหรับอุตสาหกรรม: แรงดันพิกัด 50MPa, อัตราการไหล 80L/min, เหมาะสำหรับน้ำมันไฮดรอลิกป้องกันการสึกหรอสำหรับอุตสาหกรรม (เช่น L-HM46/68) พร้อมเสถียรภาพในการทำงานระยะยาวภายใต้แรงดันสูง ให้แหล่งน้ำมันแรงดันสูงอย่างต่อเนื่องสำหรับโมดูลโหลด จำลองสภาวะการจ่ายน้ำมันจริงของเครื่องฉีดขึ้นรูปและเครื่องอัดโลหะ;

2) โมดูลถังน้ำมัน: ปริมาณใช้งานได้ 200L, ช่วงการปรับบูสต์ 0-0.3MPa (ปรับให้เข้ากับข้อกำหนดการควบคุมแรงดันของปั๊มอุตสาหกรรม) พร้อมระบบกรองสามขั้นตอน (ความแม่นยำ 10μm) เพื่อป้องกันการสึกหรอของปั๊มไฮดรอลิกที่เกิดจากการปนเปื้อนของน้ำมัน และรับประกันความสะอาดของน้ำมันและความเสถียรของการไหลเวียนภายใต้สภาวะแรงดันสูง;

3) ไดนาโมมิเตอร์ไฟฟ้า 160kW: หน่วยทดสอบกำลังหลักให้การควบคุมความเร็วแบบไม่ต่อเนื่องตั้งแต่ 0 ถึง 10,000 รอบต่อนาที รองรับการทำงานเกินพิกัด 120% (ระยะเวลาสั้น 10 นาที เหมาะสำหรับโหลดกระแทกเริ่มต้นและหยุดของปั๊มอุตสาหกรรม) ควบคุมแรงบิดคงที่อย่างแม่นยำผ่านการโหลดแรงแม่เหล็กไฟฟ้า และทดสอบประสิทธิภาพการส่งคืนพลังงาน ≥85%;

4) เซ็นเซอร์แรงบิดและความเร็ว: ช่วงแรงบิด 0-500Nm, ช่วงความเร็ว 0-10000r/min, ระดับความแม่นยำ ≤0.1% FS, การเก็บข้อมูลแรงบิดและความเร็วแบบเรียลไทม์ของปั๊มไฮดรอลิกอุตสาหกรรม ปรับให้เข้ากับความต้องการในการเก็บข้อมูลคงที่ภายใต้ภาระสูง;

5) ระบบอินเวอร์เตอร์ความถี่แปรผัน: ใช้การควบคุมแรงบิดโดยตรง (DTC) ที่มีความแม่นยำในการควบคุม ±0.01Hz; ทำงานในช่วงอุณหภูมิ 0°C ถึง 45°C (เข้ากันได้กับการเปลี่ยนแปลงอุณหภูมิในเวิร์กช็อปอุตสาหกรรม) มีระดับการป้องกัน IP54 ทำงานที่โหลดเต็ม 100% ที่ระดับความสูงต่ำกว่า 1000m มีระดับเสียง ≤85dB และรองรับโปรโตคอลการสื่อสาร Modbus สำหรับ LAN อุตสาหกรรม;

6) โมดูลโหลด: โมดูลเหล่านี้แบ่งออกเป็นสามประเภทของโหลดอุตสาหกรรม: ① โหลดระบายแรงดันสูง: โมดูลนี้ใช้กลุ่มวาล์วระบายแรงดันระดับ 50MPa เพื่อทดสอบลักษณะแรงดัน-การไหลคงที่ของปั๊มไฮดรอลิก ② โหลดควบคุมแบบสัดส่วน: โมดูลนี้ใช้วาล์วแบบสัดส่วนเพื่อจำลองการเปลี่ยนแปลงการไหลระหว่างการหนีบ/เปิดแม่พิมพ์ของเครื่องฉีดขึ้นรูป และ ③ กระบอกสูบโหลดสำหรับงานหนัก: โมดูลนี้ใช้แอคทูเอเตอร์ไฮดรอลิกคลาส 50kN เพื่อจำลองสภาวะงานหนักของการกดอุปกรณ์โลหะวิทยาและการยกเครื่องจักรการขุด

7) โมดูลวัดและควบคุม: รวมหน่วยเก็บข้อมูลหลายช่องสัญญาณ (ความถี่ในการสุ่มตัวอย่าง 300Hz เหมาะสำหรับการทดสอบสภาวะคงที่ทางอุตสาหกรรม) รองรับการเก็บข้อมูลพร้อมกันมากกว่า 150 พารามิเตอร์ รวมถึงแรงบิด, แรงดัน (0-60MPa), การไหล (0-100L/min), อุณหภูมิน้ำมัน และสร้างเส้นโค้งประสิทธิภาพเชิงปริมาตรและประสิทธิภาพรวมของปั๊มโดยอัตโนมัติ รวมถึงรายงานการทดสอบเฉพาะสำหรับอุปกรณ์อุตสาหกรรม

8) โมดูลควบคุมระยะไกล: โมดูลนี้ใช้สถาปัตยกรรม dual-core DSP+FPGA, CPU สถาปัตยกรรม X86 (ความถี่หลัก 1.0GHz, หน่วยความจำ 1GB, ดิสก์ DOM 8GB) และติดตั้งระบบ Win10 IoT Industrial Edition ไว้ล่วงหน้า รองรับการเชื่อมต่อกับระบบ MES ของเวิร์กช็อป และสามารถควบคุมได้ทั้งในพื้นที่/ระยะไกลภายในระยะ 500m ปรับให้เข้ากับความต้องการของเวิร์กช็อปไร้คนขับทางอุตสาหกรรม

3. พารามิเตอร์ทางเทคนิคของชุดทดสอบไดนาโมมิเตอร์ปั๊มไฮดรอลิกอุตสาหกรรม 160kW

| พารามิเตอร์ |

ตัวบ่งชี้ทางเทคนิค |

พารามิเตอร์ |

ตัวบ่งชี้ทางเทคนิค |

| กำลังไฟพิกัด |

160kW |

ช่วงความเร็วแรงบิดคงที่ |

0-6000rpm |

| ความเร็วเอาต์พุตสูงสุด |

10000rpm |

ช่วงความเร็วพลังงานคงที่ |

6000-10000rpm |

| ความสามารถในการโอเวอร์โหลด |

120% (ระยะเวลาสั้น 10 นาที) |

แรงบิดพิกัด |

255Nm |

| ช่วงการวัดแรงบิด |

0-500Nm (เซ็นเซอร์แบบปรับได้) |

ประสิทธิภาพการกู้คืนพลังงาน |

≥85% (กลับสู่กริด) |

| ความแม่นยำในการวัดความเร็ว |

±0.01%FS |

วิธีการระบายความร้อน |

การระบายความร้อนด้วยน้ำแบบบังคับ + วงจรการกระจายความร้อนอิสระ |

| วิธีการควบคุม |

การควบคุมแบบวงปิดสามวง (แรงบิด/ความเร็ว/กำลัง) |

แหล่งจ่ายไฟอะแดปเตอร์ |

380V±10% สามเฟส 50Hz (ต้องใช้หม้อแปลงไฟฟ้าอิสระ) |

| ความแม่นยำในการควบคุมสภาวะคงที่ |

แรงบิด ±0.2% FS, ความเร็ว ±0.1rpm |

ช่วงกำลังไฟปั๊มไฮดรอลิกที่ใช้งานได้ |

80-200kW (ครอบคลุมปั๊มกำลังไฟขนาดกลางและขนาดใหญ่สำหรับอุตสาหกรรมกระแสหลัก) |

4. มาตรฐานอ้างอิงของชุดทดสอบไดนาโมมิเตอร์ปั๊มไฮดรอลิกอุตสาหกรรม SSCH160-6000-10000 160kW

มาตรฐานภายในประเทศ

1) GB/T 3766-2021 กฎทั่วไปและข้อกำหนดด้านความปลอดภัยสำหรับระบบส่งกำลังไฮดรอลิกและส่วนประกอบ

2) GB/T 17487-2021 วิธีการทดสอบปั๊มไฮดรอลิก

3) GB/T 23537-2017 ปั๊มลูกสูบไฮดรอลิก (มาตรฐานพิเศษสำหรับปั๊มลูกสูบแรงดันสูงสำหรับอุตสาหกรรม)

4) JB/T 7039-2016 "ขีดจำกัดของค่าเสียงสำหรับปั๊มไฮดรอลิก" (ข้อกำหนดการปฏิบัติตามเสียงสำหรับเวิร์กช็อปอุตสาหกรรม)

มาตรฐานสากล

1) ISO 4413:2010 "พลังงานของไหลไฮดรอลิก - กฎทั่วไปและข้อกำหนดด้านความปลอดภัยสำหรับระบบและส่วนประกอบ"

2) ISO 10770-1:2019 "พลังงานของไหลไฮดรอลิก - ปั๊มและมอเตอร์ - ส่วนที่ 1: แรงดันพิกัด, การกระจัดพิกัด และความเร็วพิกัด" (มาตรฐานพารามิเตอร์พิกัดปั๊มอุตสาหกรรม)

3) DIN 24313:2019 พลังงานของไหลไฮดรอลิก - วิธีการทดสอบสำหรับปั๊ม

4) ISO 9906:2012 "เครื่องยนต์สันดาปภายในแบบลูกสูบ - ประสิทธิภาพ" (เหมาะสำหรับการทดสอบประสิทธิภาพของมอเตอร์ขับเคลื่อนปั๊มอุตสาหกรรม)

5. ข้อได้เปรียบหลักของชุดทดสอบไดนาโมมิเตอร์ปั๊มไฮดรอลิกอุตสาหกรรม SSCH160-6000-10000 160kW

1) ความสามารถในการทดสอบสภาวะคงที่ภายใต้ภาระสูง: ไดนาโมมิเตอร์ 160kW รองรับการทำงานในสภาวะคงที่ตั้งแต่ 0-10,000 รอบต่อนาที โดยมีความแม่นยำในการควบคุมแรงบิด ±0.2% FS สามารถทำการทดสอบสภาวะคงที่แรงดันสูง 50 MPa ของปั๊มไฮดรอลิกอุตสาหกรรมได้นาน 72 ชั่วโมงติดต่อกัน ปรับให้เข้ากับการจำลองสภาวะการทำงาน "การทำงานต่อเนื่อง 24 ชั่วโมง" ของปั๊มเครื่องฉีดขึ้นรูป

2) การปรับตัวอย่างลึกซึ้งกับแรงดันสูงทางอุตสาหกรรม: ปั๊มไฮดรอลิกคลาส 50MPa + กลุ่มวาล์วระบายแรงดันสูง ครอบคลุมข้อกำหนดการทดสอบของปั๊มลูกสูบแรงดันสูงสำหรับอุตสาหกรรมกระแสหลัก (35-70MPa) สามารถจับภาพแนวโน้มการลดลงของประสิทธิภาพเชิงปริมาตรของปั๊มภายใต้แรงดันสูงได้อย่างแม่นยำ ให้การสนับสนุนข้อมูลสำหรับการเลือกใช้ระบบไฮดรอลิกของอุปกรณ์อุตสาหกรรม;

3) ข้อดีด้านการประหยัดพลังงานและต้นทุน: ด้วยประสิทธิภาพการส่งกลับพลังงานมากกว่า 85% ระบบจะกู้คืนไฟฟ้าประมาณ 136kWh ต่อชั่วโมงที่โหลดเต็ม 160kW ประหยัดค่าใช้จ่ายด้านพลังงานต่อปีมากกว่า 60% เมื่อเทียบกับชุดทดสอบโหลดแบบต้านทานแบบดั้งเดิม เหมาะอย่างยิ่งสำหรับการตรวจสอบคุณภาพแบบกลุ่มและการทดสอบความทนทานในระยะยาวของปั๊มอุตสาหกรรม

4) การจำลองสภาวะการทำงานทางอุตสาหกรรมหลายแบบ: โมดูลโหลดรองรับการสลับสามโหมด: การล้นแรงดันสูง (การกดโลหะวิทยา), การควบคุมแบบสัดส่วน (การหนีบการฉีดขึ้นรูป), และการโหลดสำหรับงานหนัก (การยกการขุด) การทดสอบประสิทธิภาพของปั๊มในสถานการณ์อุตสาหกรรมที่แตกต่างกันสามารถทำได้โดยไม่ต้องเปลี่ยนอุปกรณ์

5) การปรับตัวของเวิร์กช็อปอุตสาหกรรม: ระบบอินเวอร์เตอร์ความถี่แปรผันมีคุณสมบัติการป้องกัน IP54 และการระบายความร้อนด้วยน้ำแบบบังคับ ทำให้สามารถปรับให้เข้ากับสภาพแวดล้อมที่มีฝุ่นและอุณหภูมิผันผวนของเวิร์กช็อปอุตสาหกรรม นอกจากนี้ยังรองรับการรวมโปรโตคอล Modbus กับระบบ MES ของเวิร์กช็อป ทำให้สามารถเชื่อมโยงข้อมูลการทดสอบกับระบบการจัดการการผลิตได้

6) การออกแบบความน่าเชื่อถือสูง: ส่วนประกอบหลักของไดนาโมมิเตอร์ทำจากวัสดุที่ทนทานเกรดอุตสาหกรรม (เช่น ตลับลูกปืนซีรีส์สำหรับงานหนักของ SKF) โดยมีเวลาบำรุงรักษาประจำปี ≤30 ชั่วโมง ระบบกรองถังน้ำมันสามขั้นตอนช่วยลดการสึกหรอของปั๊มไฮดรอลิกและยืดอายุการใช้งานของอุปกรณ์ทดสอบ

6. การใช้งานระบบไดนาโมมิเตอร์ปั๊มไฮดรอลิกอุตสาหกรรม SSCH160-6000-10000 160kW

1) การทดสอบปั๊มไฮดรอลิกเครื่องฉีดขึ้นรูปสำหรับงานหนัก: มุ่งเป้าไปที่ปั๊มลูกสูบแรงดันสูง 35-50MPa ในเครื่องฉีดขึ้นรูป การทดสอบนี้จะวัดลักษณะแรงดัน-การไหลและประสิทธิภาพเชิงปริมาตรภายใต้สภาวะการหนีบ/การฉีดขึ้นรูป เพื่อให้มั่นใจถึงความเสถียรในการขึ้นรูปของผลิตภัณฑ์ฉีดขึ้นรูป

2) การตรวจสอบระบบไฮดรอลิกเครื่องจักรโลหะวิทยา: ปรับให้เข้ากับปั๊มไฮดรอลิก 40-60MPa ที่ใช้ในเครื่องอัดโลหะวิทยาและโรงรีด จำลองสภาวะอุณหภูมิสูงและโหลดหนัก และตรวจสอบความน่าเชื่อถือในการทำงานในระยะยาวและคุณสมบัติการเตือนความผิดพลาดของปั๊ม;

3) การตรวจสอบคุณภาพปั๊มไฮดรอลิกเครื่องจักรการขุด: ให้การสอบเทียบประสิทธิภาพจากโรงงานสำหรับปั๊มหลักไฮดรอลิก (30-50MPa) ของรถขุดและรถตักสำหรับการขุด ทดสอบการควบคุมที่ไวต่อโหลดและความสามารถในการป้องกันมลพิษ และรับประกันความพร้อมใช้งานของอุปกรณ์ในสภาพแวดล้อมการขุดที่รุนแรง;

4) การทดสอบเครื่องจักรบนดาดฟ้าเรือ: สำหรับปั๊มไฮดรอลิก 30-40MPa ที่ใช้ในกว้านสมอเรือและกว้าน จะมีการทดสอบเอาต์พุตแรงบิดและประสิทธิภาพภายใต้สภาวะความเร็วต่ำและโหลดหนัก เพื่อให้เป็นไปตามข้อกำหนดด้านความน่าเชื่อถือของอุตสาหกรรมการต่อเรือ;

5) การวิจัยและพัฒนาและปรับปรุงปั๊มไฮดรอลิกอุตสาหกรรม: ให้การวิจัยและพัฒนาและการทดสอบปั๊มกำลังไฟขนาดกลางและขนาดใหญ่ 80-200kW สำหรับผู้ผลิตปั๊มไฮดรอลิก ปรับโครงสร้างการซีลแรงดันสูงและการออกแบบแผ่นกระจายของปั๊มให้เหมาะสม และเพิ่มขีดความสามารถในการแข่งขันของผลิตภัณฑ์

7. รายการรุ่นชุดทดสอบไดนาโมมิเตอร์ปั๊มไฮดรอลิกอุตสาหกรรม

| รุ่น |

การกำหนดค่าหลัก (ไดนาโมมิเตอร์ไฟฟ้า) |

ความเร็วทดสอบสูงสุด |

ปรับแรงดันปั๊มไฮดรอลิก |

| SSCH11-15000-35000 |

11kW, 7Nm |

35000rpm |

≤30MPa |

| SSCH22-15000-30000 |

22kW, 14Nm |

30000rpm |

≤35MPa |

| SSCH37-15000-25000 |

37kW, 24Nm |

25000rpm |

≤40MPa |

| SSCH55-15000-20000 |

55kW, 35Nm |

20000rpm |

≤50MPa |

| SSCH80-6000-15000 |

80kW, 127Nm |

15000rpm |

≤40MPa |

| SSCH110-6000-12000 |

110kW, 175Nm |

12000rpm |

≤45MPa |

| SSCH160-6000-10000 |

160kW, 255Nm |

10000rpm |

≤50MPa |

| SSCH220-6000-8000 |

220kW, 350Nm |

8000rpm |

≤60MPa |

| SSCH315-3000-6000 |

315kW, 501Nm |

6000rpm |

≤70MPa |

| หมายเหตุ |

รองรับการปรับแต่งโมดูลกำลังไฟ ความเร็ว และโหลดตามความต้องการของลูกค้า (เช่น การเพิ่มห้องสิ่งแวดล้อมอุณหภูมิสูงและโมดูลทดสอบป้องกันมลพิษ) |

ตอบ: รอบการผลิตไดนาโมมิเตอร์คือ 6-8 สัปดาห์ รอบการผลิตเซ็นเซอร์คือ 2-3 สัปดาห์ สำหรับผลิตภัณฑ์อื่นๆ โปรดติดต่อเรา

ตอบ: ฝากอีเมลของคุณไว้ เจ้าหน้าที่ด้านเทคนิคของเราจะสื่อสารกับคุณเกี่ยวกับแผนโดยละเอียด

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!  ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!